How manufacturers can improve their business competitiveness

Earthing and lightning solutions in manufacturing concerns are often overlooked or neglected at the peril of manufacturers. Safety, reliability and productivity suffer while maintenance costs soar.

By simply implementing improvements in earthing and lightning, manufacturers can mitigate risks, improve operational efficiency, and ultimately increase their bottom line.

Here are 5 steps to assuring effective Earthing and Lightning solutions in manufacturing facilities:

#1. Conducting a Comprehensive Risk Assessment to Relevant Standards to IEEE Std 80, 142 &1100, BS 7430

Here you should identify potential hazards related to earthing and lightning, such as electrical surges, equipment damage, and the risk of fire….By understanding the specific risks that exist within the manufacturing facility, appropriate measures should be addressed in design, construction or upgrades.

#2. Designing an Effective Earthing System Design

An effective earthing system forms the foundation of a safe and reliable electrical infrastructure. It provides a low-resistance path for electrical faults, preventing electric shocks and minimizing the risk of fire.

Upgrading the earthing system involves ensuring proper grounding of equipment, implementing surge protection devices, and considering the use of isolated grounding systems for sensitive equipment. These enhancements reduce the likelihood of electrical failures, equipment damage, and production downtime.

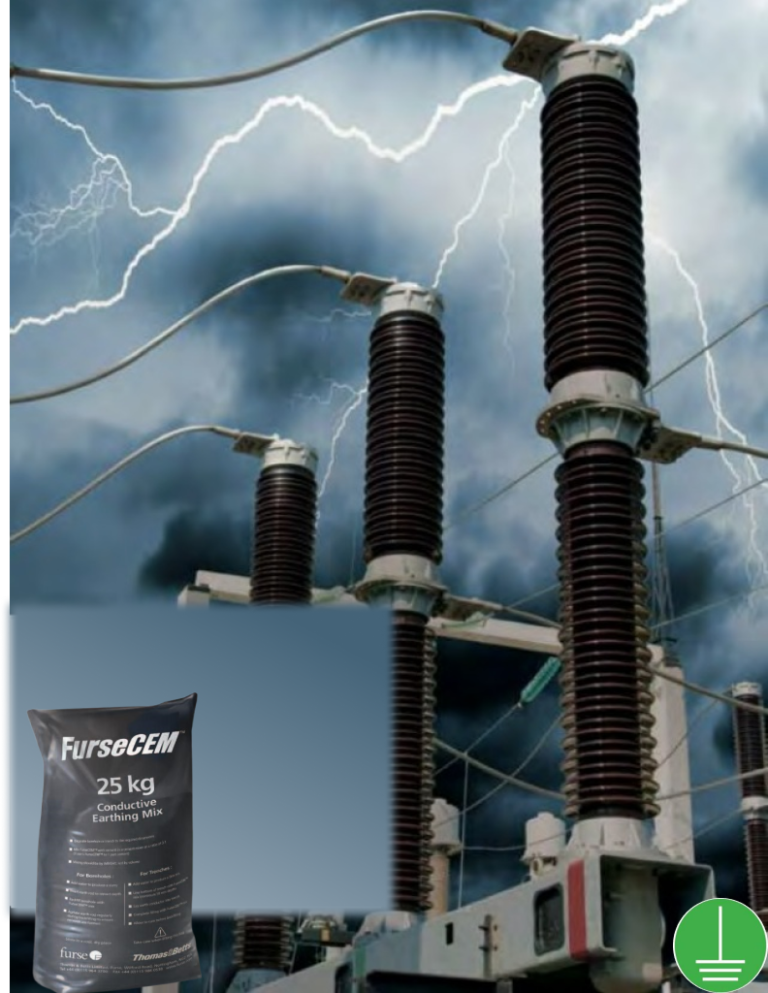

#3. Implementing Lightning Protection Measures to IEC/BS EN 62305 & NFPA 780

Lightning strikes pose a significant risk to manufacturing facilities, as they cause severe damage to equipment, disrupt operations, and endanger personnel.

Implementing lightning protection measures to IEC/BS EN 62305, NFC 17-102, such as air termination network, down conductor, earth termination network and bonding, surge protective devices, can ameliorate lightning effects on critical infrastructure. This proactive approach safeguards costly equipment failures, downtime, and potential injuries.

#4. Regular Maintenance and Inspection to IEC/BS EN 62305 & NFPA 780

This is to ensure the continual integrity and effectiveness of the earthing and lightning solutions, regular maintenance and inspection is essential and should be carried out at least once yearly. It includes and not limited to testing of grounding systems, inspection of lightning protection system, and the identification and rectification of any deficiencies. Having a proactive maintenance plan is a sure way to address potential issues before they escalate, thus ensuring ongoing safety, reliability, and productivity of operations.

#5. Training and Education

Improving safety, reliability, productivity, and profits requires a well-informed workforce. Providing training and education on the importance of earthing and lightning solutions fosters a culture of safety awareness among employees. This empowers responsible staffs to identify potential risks, report any concerns, and follow proper protocols to minimize hazards. Additionally, training must include standards and guidelines on best practices for equipment grounding, surge protection, and lightning safety.

In the manufacturing industry, investing in improvements to earthing and lightning solutions is a strategic choice that can yield significant benefits.

By conducting a comprehensive risk assessment, designing an effective earthing system, implementing lightning protection measures, maintaining and inspecting the infrastructure, and providing training and education, manufacturers can enhance safety, reliability, productivity, and profits.

These improvements not only safeguard personnel and equipment but also optimize operational efficiency, reduce downtime, and ultimately contribute to the long-term success of the manufacturing facility.

@Fullspectrum, we take pride in our solutions that adhere to the highest standards and best practices.

Enquiries

victor Oyedu, FNSE, FNIEEE, CPQ.

Power Quality and Energy Management Specialist.

Publisher at Afrienergyonline.com

CEO, FullSpectrum Energy Solutions Limited, Nigeria.