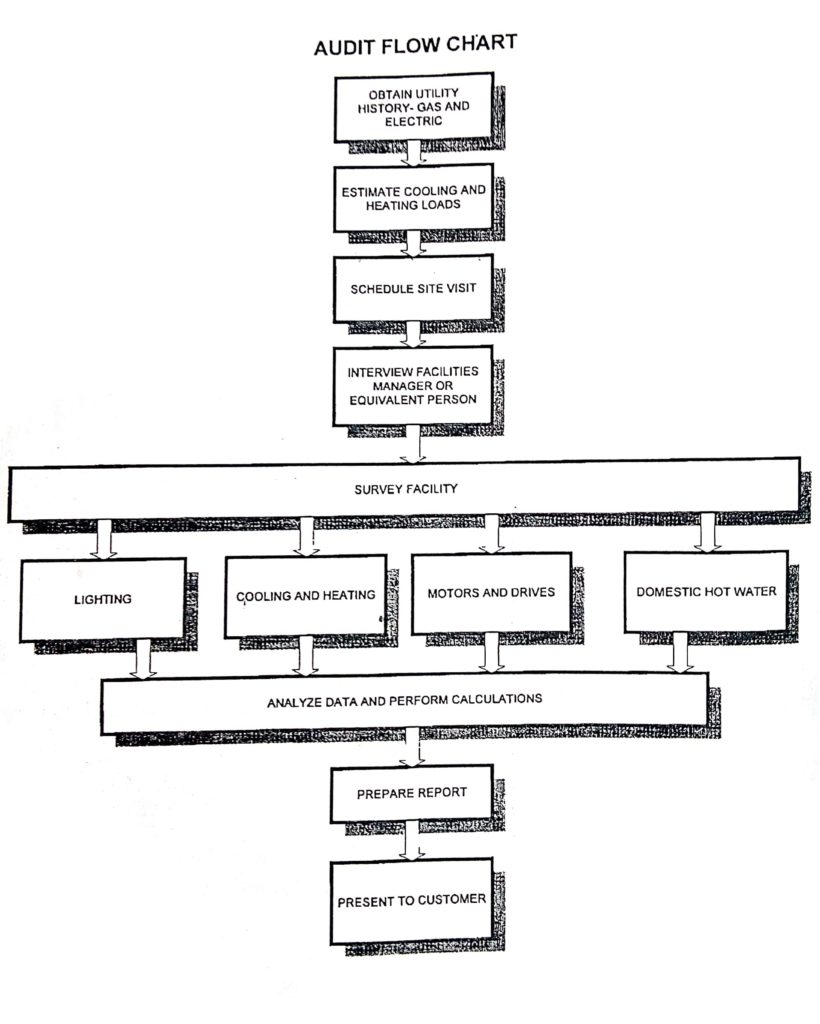

Having gone through the previous steps of obtaining utility bills, estimated heating and cooling loads, Site visitation, meeting with the facility manager (s) or equivalent (s) and concluded the facility survey.

Our next steps will be to put it all together by analyzing the data collected and calculations for step 6. The final step 7 being the preparation of the energy audit report.

Step 6: Analyzing data and performing calculations

Usually done in the office, using hand calculations, spreadsheets and/or simulation programs. Potential savings for each Energy Conservation Measure and paybacks are calculated.

Typically measures with over a five year payback are not listed unless requested by the customer. Simple paybacks are usually calculated but big corporations and some government agencies in most cases require the life cycle costing to form the basis for decision making.

Steps 7: Report preparation

The final stage of energy auditing is the report comprising the Executive Summary, Building Information, Utility Summary, Energy Conservation Measures (ECMs), Operation and Maintenance Measures (O & Ms), Recommended M & V methods, Future Action and Appendices.

This can be best captured with the energy report template below.

However it may vary depending on the type of audit: industrial, commercial or home and their complexities.

Executive Summary

- Brief, simple and straight to the point

- Introduction to project

- Summary table of ECMs (Energy Conservation Measures)

- Performance of measures

- Discussion of issues important to client

- Benefits to client

- Future action items

Building Information

- Envelope description

- Floor plans

- Operating schedule

- Occupancy patterns

- Energy use in the plant

- Mechanical systems

Utility Summary

- Energy accounting data and graphics for the previous two years

- Energy use index (EUI)

- Monthly consumption profiles

- Demand profile

- Rate schedules/rate alternatives

- Avoided costs to be used in calculations

Energy Conservation Measures (ECMs)

- List of ECMs that meet financial criteria

- Descriptions

- Energy calculations

- Simple payback and/or NPV, SIR, IRR

- ECMs considered but not recommended

Operation and Maintenance Measures (O and Ms)

- Operation maintenance practices

- Description of low-cost improvements

- Potential operational changes

- Maintenance issues affecting energy use

- Energy and equipment savings estimates

- Costs to implement measures

- Impact on Personnel

Recommended M & V methods to verify savings

- Name of software used and version

- Items to be measured

- Measurement duration recommendations

- Measuring equipment, data loggers, etc

Future Action Items

- Additional studies?

- Building simulation required?

- Future action items

Appendices

- Floor plans, site notes, photos

- Audit data forms

- Computer simulation runs if applicable

- Motor and lighting and equipment inventory

- Energy program information and applications

We cannot conclude without mentioning the basic tools and instruments that are helpful in getting the job done.

ENERGY AUDIT EQUIPMENT LIST

Basic Audit Tools

The needed tools in performing an audit are:

- Flashlight

- Digital camera

- Clipboard

- Small mirror

- Measuring tape

- Digital counter

- Binoculars

- Rag

- Safety glasses

- Hardhat

- Hearing protection

- Any safety equipment required by the facility

- Etc

Advance Equipment (for higher level audits)

However, the more detailed the audit, the more equipment required.

Also, the higher the level of audit, the more measurements required. The type of equipment that will be needed depends upon the type of energy-consuming equipment used at the facility, and on the potential energy conservation measures.

- Multi-meter

- Light meter

- Ballast discriminator

- Power meter

- Combustion analyzer

- Thermometer

- Tachometer

- Air velocity meter

- Pressure meter

- Data loggers

- Psychrometer

- Steam trap leak detector

- Thermal imaging camera

- Etc

Contact us

Victor Oyedu, FNSE, FNIEEE, CPQ.

Power Quality and Energy Management Specialist.

Publisher at Afrienergyonline.com &

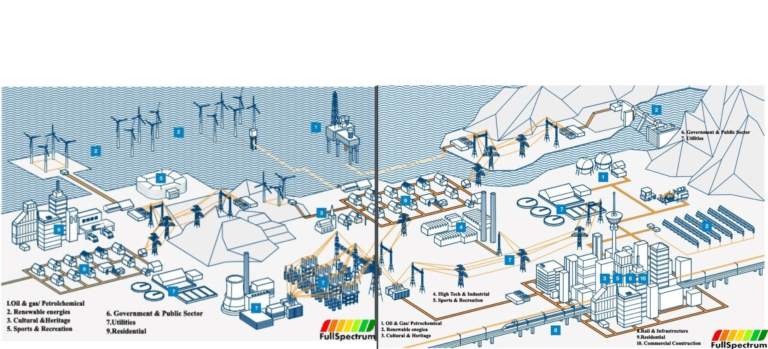

CEO, FullSpectrum Energy Solutions Limited, Nigeria.

1 Comment

Sure