This section concludes the various types and general characteristics of lamps.

METAL HALIDE LAMPS

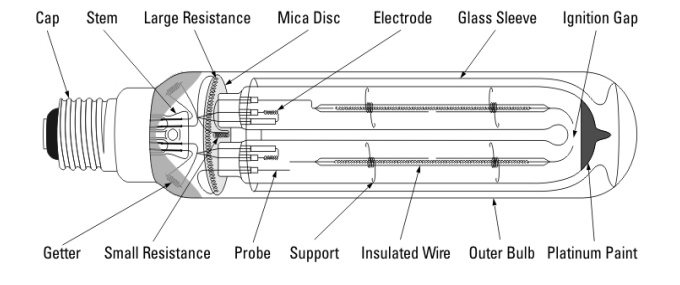

Metal halide lamps, also classified as HID lamps, are similar in design to mercury vapour lamps.

The primary difference is that metal halides are used in addition to mercury inside the bulb.

Metal halides are 1.5 to 2 times more efficient than mercury vapour lamps.

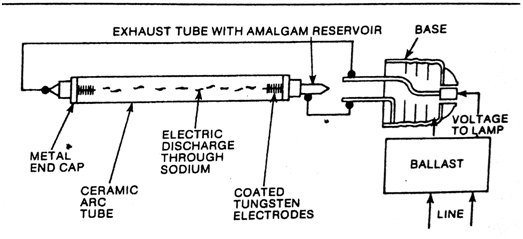

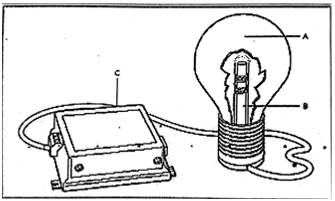

A pictorial view of a metal halide bulb and the associated circuitry as shown below

Metal Halide Lamp Strengths

- Applicable for general lighting

- Relatively long lamp life up to 20000 hours

- May be interchangeable with mercury lamps in some applications

- Good colour rendition – output is a crisp white light

- More efficient than mercury vapour, incandescent and most fluorescents

Metal Halide Lamp Weaknesses

- Shorter life than other HID lamps

- Some lamps must be used in base-up vs base-down positions

- Requires a ballast

- Lamps require a 2 to 5 minute warm up period

- Lamps have to cool down up to 10 minutes before restarting

- Some lamps require closed fixtures due to lamp breaking upon failure

Improvement Opportunities

- Replace mercury vapour lamps with metal halides when good colour rendition is an issue

- Evaluate high bay lighting

HIGH BAY FLUORESCENTS

High bay fluorescents have been slowly replacing the round high bay fixtures in many facilities. These fixtures can contain either T-8 or T-5 bulbs. Since the photometric pattern and lumen output from these high bay fluorescents is different than the typical round metal halide high bay fixtures, it is recommended that a lighting design be performed to determine the best layout. One-for-one replacements tend to result in over lighting.

High Bay Fixtures- Metal halide (up) and T-5 (down)

HIGH PRESSURE SODIUM LAMPS

High pressure sodium lamps (HPS), also members of the HID group, are constructed with two glass envelopes. Xenon is typically used as a starting gas inside the arc tube, which also contains small amounts of sodium-mercury amalgam. These chemicals are vapourized once the lamp reaches operating temperature and give the lamp its golden yellow colour.

HPS are the most efficient members of the HID family that still give some degree of colour rendition. Approximately 30% of the input energy is converted to useful light output. Figure 3.10 shows a sodium vapour bulb and the associated circuitry.

High Pressure Sodium Lamps

HIGH PRESSURE SODIUM STRENGTHS

- Most efficient member of the HID family when some colour rendition is required

- Warm-up period is 3 to 4 minutes-less than the mercury vapour or metal halides

- Long lamp life. Up to 24000 hours

- Excellent lumen maintenance

- Wide range of lamp types and wattages available

High Pressure Sodium Weaknesses

- The light produced is yellow which may not be satisfactory in some applications

- Requires ballast

- Lamp cycles on and off at end of life

Improvement Opportunities

- If colour rendition is not critical, HPS lamps can replace all types of outdoor applications

- In warehouse or storage situation, HPS lamps can reduce other types of lighting if colour rendition is not an issue

- Evaluate high bay fluorescents

LOW PRESSURE SODIUM LAMPS

Low pressure sodium lights (LPS), members of the HID group, are one of the most efficient sources of light commercially available. These lamps, however, are used in few applications due to their extremely poor colour rendition.

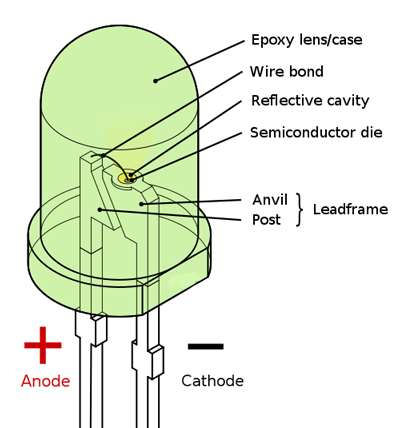

LEDs (Light Emitting Diodes)

When an electric current is passed through a diode (an electronic device that only lets current flow in one direction), light is produced. LEDs are designed to allow this light to emit from the diode.

LEDs have been around since the 60s, but have only been relegated to showing the time in an alarm clock or the battery level of a video camera. They haven’t been used as sources of illumination because for a long time, they could not produce white light – only red, green and yellow. Nichia Chemical of Japan changed that in 1993 when it started producing blue LEDs, which combined with red and green produced white light, opening up a whole new field for the technology. Current white LEDs can last up to 50000 hours, about 50 times as long as a 60-watt bulb. Heat produced by the electronics can be a problem with LEDs, as it shortens their life. The lpw watt currently available is in the 30-90 range. Lpws greater than 200 have been achieved but these products are not currently commercially available.

INDUCTION LIGHTING

Induction lighting uses a high frequency generator that induces current and consequentially gas discharge in the bulb. No electrodes are used in the bulb, and the result of this technology is a long lamp-life, projected to be 100,000 hours. The lpw of these lamps is in the 70-80 lpw range and the CRI around 80. Applications include high bay and wall mounted lighting. A good application for induction lighting is for hard to reach areas, where changing the bulb would be difficult. The long life of induction lighting would minimize bulb replacement.

Induction Lighting

KEY:

- Discharge vessel

- Power coupled tube

- Electronic driver

Contact us

Victor Oyedu, FNSE, FNIEEE, CPQ.

Power Quality and Energy Management Specialist.

Publisher at Afrienergyonline.com &

CEO, FullSpectrum Energy Solutions Limited, Nigeria