Before stating an energy audit, it is helpful to have some idea of the scope of the project and the level of effort necessary to meet expectations.

Here we shall discuss the levels of surveys and assessments necessary to perform commercial building or industrial audits.

American Society of Heating Refrigerating and Air conditioning Engineers (ASHRAE) in the book “Procedure for Commercial Building Energy Audits” identified three levels of energy audits.

But we shall be considering four levels of energy audits from the basic level to the more complex types(levels): types or levels 0, I, II, lll

Types of energy audit

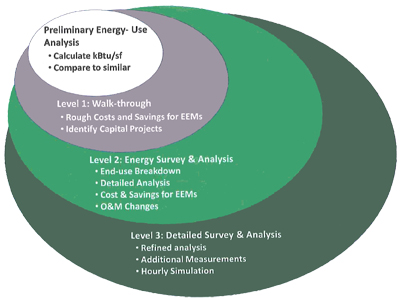

TYPE 0 – The Benchmarking Audit

The benchmarking type involves a detailed preliminary analysis of energy use and cost.

To determine benchmarking indices like BTU per square foot per year called Energy Use Index (EUI) and dollar energy cost per square foot per year, Energy Cost Index (ECI) based on the utility bills.

The ECI and EUI are used for the benchmarking and very cost effective for multiple facilities.

Type 1 – The Walk-Through (one-day) Audit

Involves a tour of the facility with the facility engineer or operator, hence its name walk-through or one-day audit.

To inspect each of the energy using systems and evaluating the energy consumption data, analyzing energy use quantities and patterns as well as provide comparison to industry averages or benchmarks for similar facilities

Often cheap, yielding preliminary estimates of savings potential and providing long list of low-cost savings opportunities through improvements in operational and maintenance practice. The savings may be up to 15% or more. Level one audit provides information for the more detailed standard audit.

Type II – Standard or General Audit

The level II audit goes on to quantify energy uses and losses through a more detailed data and analysis of equipment, systems and operational characteristics. It may include on-site measurements and testing to quantify energy use and efficiency. It will also include

- List of all Energy conservation measures ECMs that will save energy

- List of ECM’s deemed Practical by owner with

- implementation costs

- Energy savings

- Impact on Energy use Index (EUI)

- Possible interaction with other systems

- Estimate impacts on operations and maintenance (O & M)

- List of modifications not pursued with reasons.

- Identification of Measurements and Verification(M &V)methods required to evaluate effectiveness of the practical modifications when implemented

- Identification of all capital intensive modifications that may require a level III audit

Usually with short payback period and average investment yields can be up to 30% savings or more. Most facilities find level II audit to be sufficient..

Type III – Investment –Grade Audit

This level of assessment and analysis digs into details of any large capital retrofit project, you may be considering previously in simpler audits.

But more detailed data is gathered, extensive test measurements taken, spot measurements and short term energy monitoring carried out.

Intensive engineering and economic analysis done to produce reliable estimates. With good Return on Investment (ROI) to shore high confidence of investors for the major project. Energy savings after retrofit and engineering can be up to 60%.

A computer stimulation is usually performed in the investment grade or level III audit.

The three levels of audits (I, II, III) tend to overlap in practice and are similar in that they all assess the potential energy savings, initial costs, rate of return and payback of various energy savings strategies.

The difference is in how detailed, confident and accurate the Energy Conservation of measures or Opportunities (ECMs or ECOs) are and the cost of implementing them.

All level II and III audits involve general facility data like location, size, usage type, energy sources and cover but not limited to the following systems:

- Building Envelope.

- HVAC System .

- Electrical Supply System

- Lighting

- Boiler and Steam System.

- Hot Water System.

- Compressed Air System.

- Motors .

- Special Purpose Process Equipment.

- Water and Sewer System.

We shall subsequently be discussing the above Systems along with how to identify their Energy conservation opportunities ECOs to save energy and cut costs.

Contact us

Victor Oyedu, FNSE, FNIEEE, CPQ.

Power Quality and Energy Management Specialist.

Publisher at Afrienergyonline.com

CEO, FullSpectrum Energy Solutions Limited, Nigeria.