Electric motors convert electrical energy into rotational mechanical energy. The motors are either AC or DC powered. Altogether they consume an estimated 50% of global electricity.

Electric motors are highly efficient, reliable, offer long lasting service and cost relatively little to maintain. They come in sizes of thousands to fractions of a horsepower (1 HP= 0.746kW).

They have found applications in homes, mining, agriculture, manufacturing, processes etc. Even in commercial facilities they are used to perform special functions in chillers, air compressors, lifts, pumps etc.

An approximate sector distribution of motors is shown below

| Residential | 40% |

| Commercial Sector | 48% |

| Industrial Sector | 65% |

Despite these advantages, electric motor’s operational cost are high, to the extent that the annual running costs can often be up to 10 times the cost of the initial purchase price.

In an era of extreme competitiveness and energy cost management, care in motor selection, operation and maintenance are vital. The wide spread applications of electric motors in almost every facility makes them excellent candidates for improvements.

Improving their efficiency, loading, power factor and indeed their utilization in operations and processes all add to proper cost management of energy.

In fact marginal improvement in efficiency results in significant savings in energy operating costs.

We shall therefore look at the various types of electric motors and concentrate on three phase induction motors with a view of reducing operational cost.

Types of electric motors

Below shows the family tree of motors.

DC MOTORS

Direct current electric motors are excellent for control, particularly tight speed control, regenerative braking, large starting and running torque. Moreover it is battery operated and very portable.

Advantages

DC motor speed can be controlled smoothly down to zero and immediately followed by acceleration in opposite direction without power switching. Used mainly in applications requiring quick stops, thus eliminating the need for, or reducing the size of mechanical brake. Commercially, these motors are used in lifts and elevators.

Industrially, dc motors find applications where the speed-torque relationship can be varied to almost any useful form and either direction of rotation.Continuous operation of dc motors is commonly available over a speed range of 8:1.

ECM OR BRUSHLESS DC Motors

Brushless DC motors also known as Electronically Commutation Motors (ECM) are electric motors powered by direct current (DC) electricity and having electronic commutation systems rather than mechanical commutations and brushes. These motors are usually less than one HP.

Design

ECM motors have permanent magnets which rotate and a fixed armature, eliminating the problems of connecting current to the moving armature with brushes. An electronic controller replaces brushes/ commutator assembly of brushed DC motor, which continually switches the phase to the windings to keep the motor turning. The controller performs the similar timed power distribution by using solid-state circuit.

Application

Trending today in HVAC and refrigeration industries, is the use of ECM motors instead of various types of AC motors. Significantly because of of dramatic power savings against a typical AC motor. Fans are also using ECM motors in order to increase overall system efficiency as a replacement to the once dominated shaded-pole and permanent split capacitor motors. .

Further to the ECM motor’s high efficiency, certain HVAC systems (especially those featuring variable speed and/or load modulation) use ECM motors because of built-in microprocessors that allows easy programmability, better control over airflow and serial communication.

THREE PHASE (AC) INDUCTION MOTORS

AC induction motors range from a 1/8 to 500 horsepower. All AC motors above 1 HP are mostly 3 phase and constitute about 85 and 90% of motors in use.

The focus on 3 phase AC induction motors is obvious for the following reasons:

- Simple in design

- Rugged

- Low cost

- Reliable

- Single phase not practical in large HPs (too much current)

- Adaptable to Variable Frequency Drives (VFDs)

For the purposes of energy optimization, we shall look at several parameters or characteristics of three phase induction motor.

MOTOR SPEED

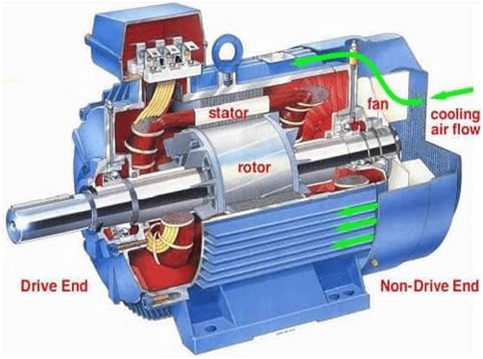

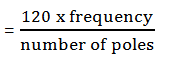

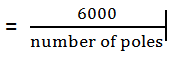

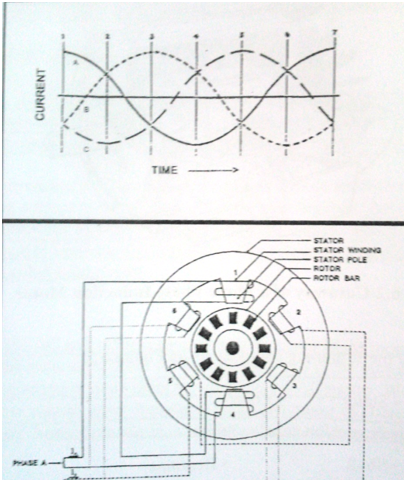

The speed of a three phase induction motor depends on the number of poles per phase in the motor, and the frequency of the alternate current. The speed of the rotating magnetic field is called the synchronous speed.

Synchronous speed

For 50Hz frequency (Nigeria)

For 60Hz frequency (US)

Synchronous Speed Diagram

Majority of motors in use in Nigeria are 2, 4 and 6 poles (or 3,000 Rpm 1,500 Rpm or 1,000 Rpm motors respectively). By using belts, pulleys, gear and VFD’s etc, any load speed can be obtained. Note that the motor shaft rotates. The full load RPM on the nameplate reflects the actual shaft speed and is a little slower than the synchronous speed

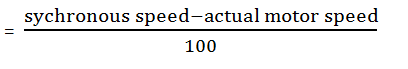

Slip = synchronous speed – actual shaft speed (expressed as a percentage slip)

The operating speeds below represent a 3% slip at 50Hz

| No of poles | Synchronous speed RPM | Operating speed RPM |

| 2 | 3,000 | 2,910 |

| 4 | 1,500 | 1,455 |

| 6 | 1,000 | 970 |

| 8 | 750 | 727.5 |

Slip

At FullSpectrum Energy, we understand that appropriate Selection, Operation, Maintenance and Proper Wiring of electric motors translate to seamless productivity and profitability i.e Motor Economic

CONTACT US

Victor Oyedu, FNSE, FNIEEE, CPQ

Power Quality and Energy Management Specialist.

Publisher at Afrienergyonline.com &

CEO, FullSpectrum Energy Solutions Limited, Nigeria